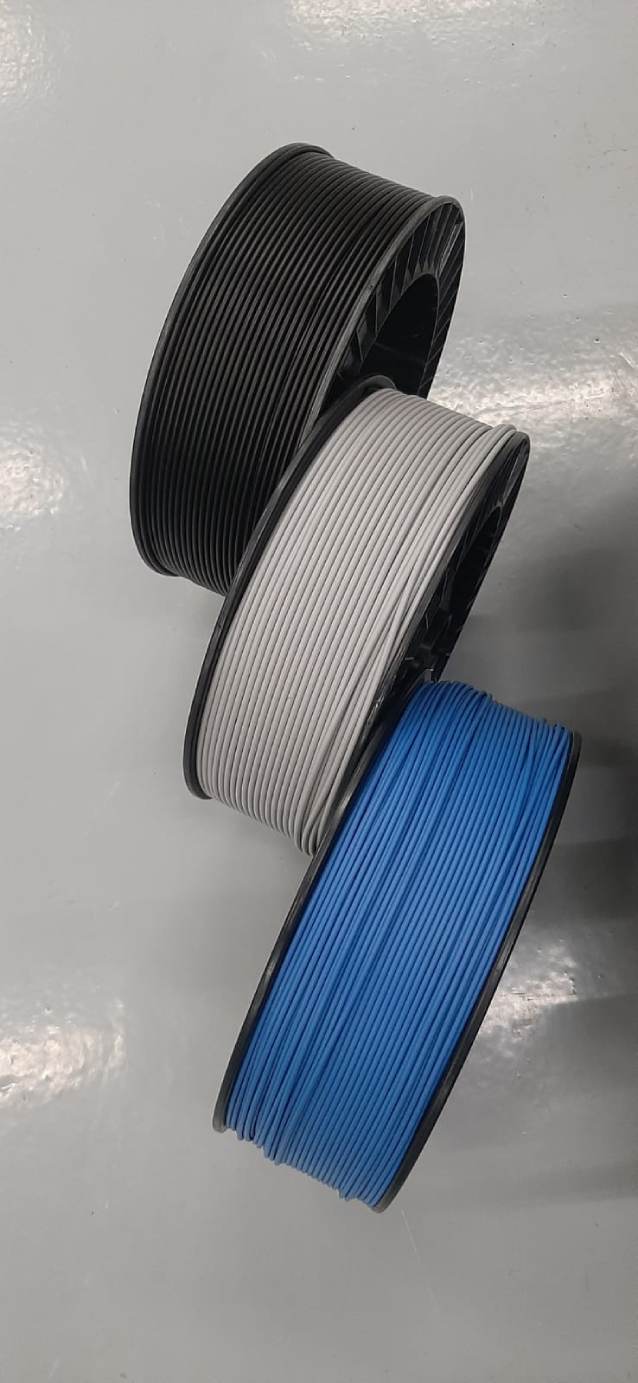

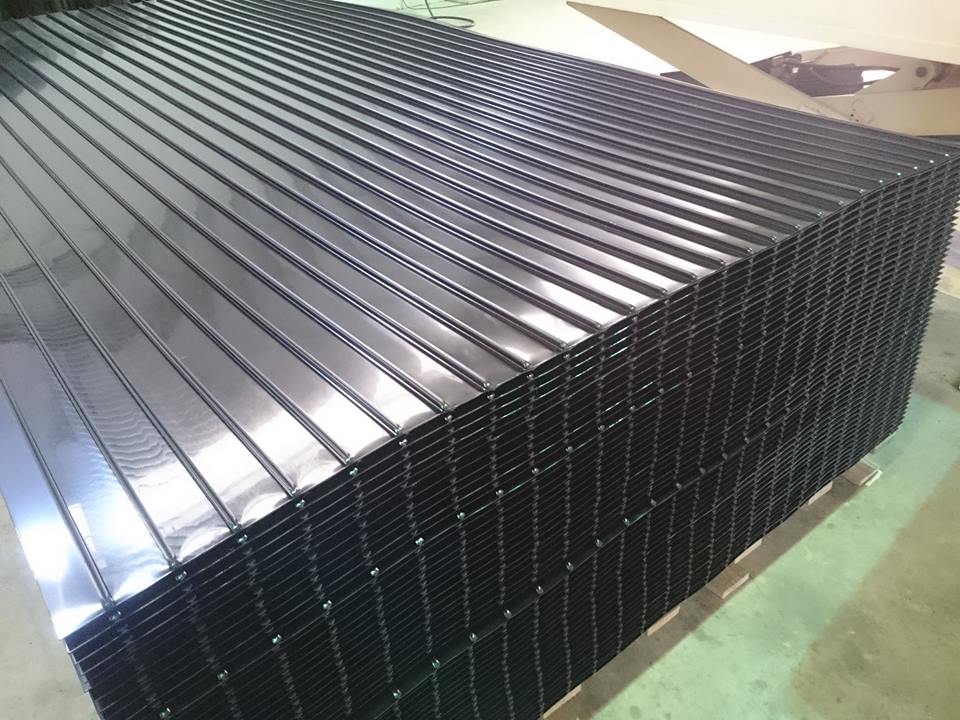

A HDPE version of our T-Lock offering outstanding chemical and physical resistance. Sheets are joined together by an extrusion process using molten HDPE welding rods.

The high chemical resistance of HDPE, along with proven welding and testing systems, ensure that sewerage treatment plants, pump stations, manholes, precast reinforced concrete pipes and other concrete structures, which operate in chemically aggressive environments, are provided with long term protection against corrosion. Additional benefits, like raised carrying capacity, through a low friction coefficient, when used for liquid conveyance, make this a cost-effective solution for a wide variety of lining applications.

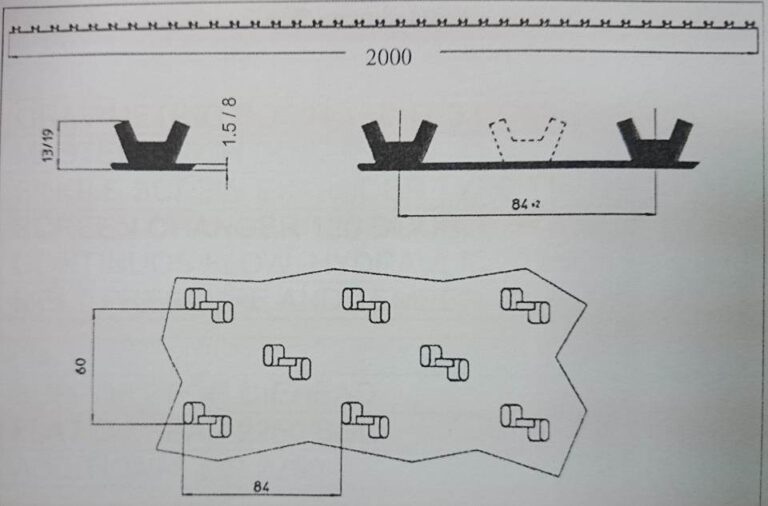

A studded version of our HDPE T-Lock that allows for better concrete flow around the studs make this product ideal for reverse lining applications.

The membrane is placed with the studs facing the concrete structure, typically reservoirs, water tanks, or for sewer rehabilitation, and either an epoxy grout or non-shrink grout, depending on the project requirements, is injected in between the membrane and the structure, allowing the membrane to be fully attached to the structure. Joints are sealed by using an extrusion welding process.

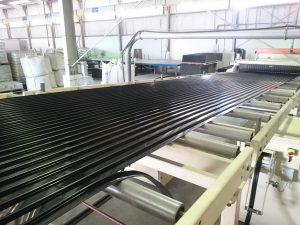

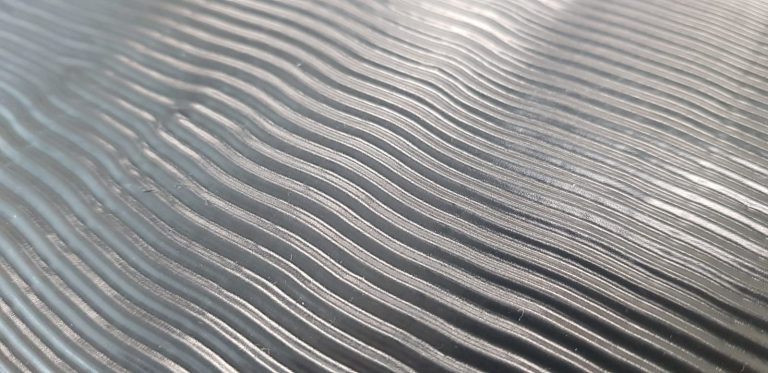

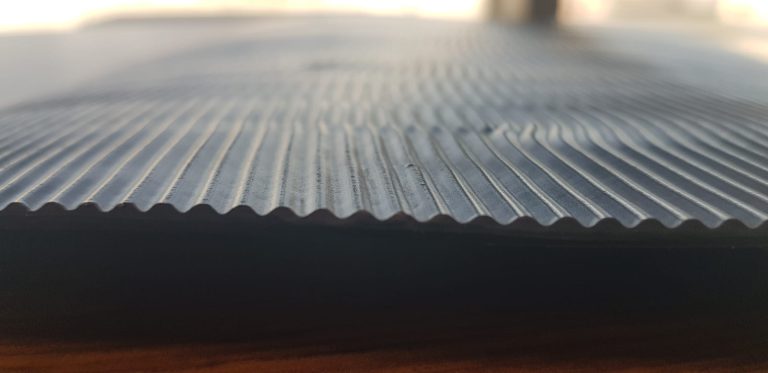

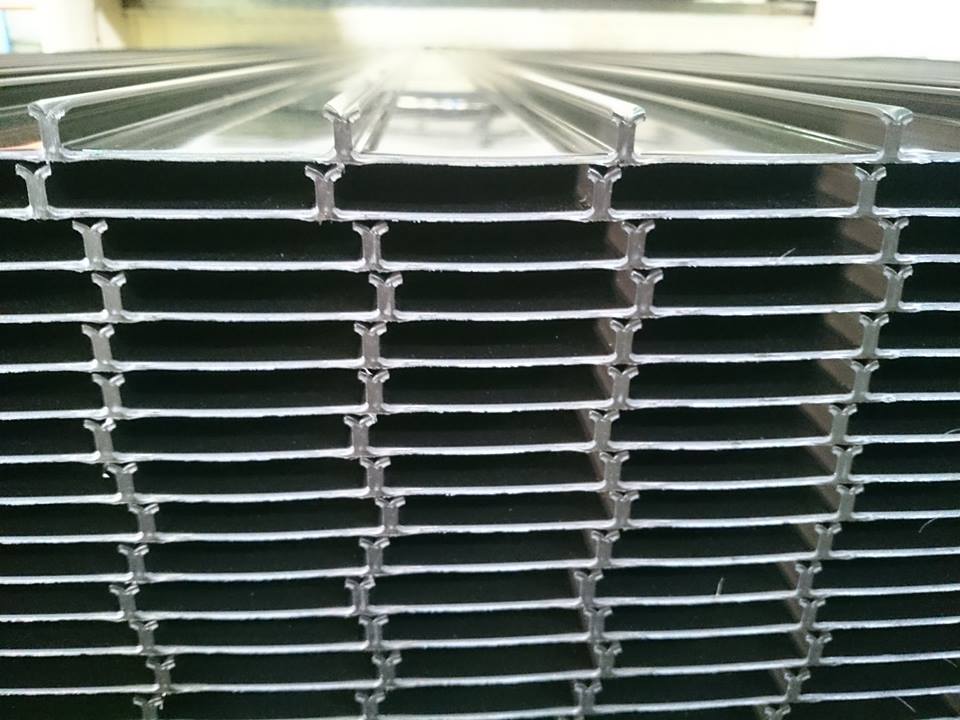

T-Lock Plastic sheet is a T-ribbed membrane that is flat on one side, while the reverse side contains parallel T-Shaped ribs. These ribs are cast into concrete at the new construction stage, thus isolating the concrete from the harmful effects of corrosive chemicals.

The evolution of the T- Lock Linings represents a major breakthrough in physical properties, with elongation at break point being to the order of 600% for polyethylene T-Lock lining will therefore not crack when placed under stress, like coatings and they will endure for over 50 years in the toughest of service.

Document

Document